flue gas analysis parameters|orsat analysis of flue gas : purchaser Flue gas analyzers are crucial for sustaining efficient combustion processes, managing emissions, and guaranteeing worker and environmental safety. By comprehending flue gas components and the role of these .

WEBDaniela cicarele fazendo sexo na praia 4 min. 1,401,2891M. 97.1 % 2.9 % 1,186 votes. 866 320. 97.1%. 2.9%. 5 Comments Download Save Share Report. Copy page link. Embed .

{plog:ftitle_list}

webTed2023 É a maior buceta do Brasil! Pamella @pmellamakeup pictures and videos on .

Using a Flue Gas Analyzer or any meter designed to measure oxygen or carbon-monoxide, and taking the flue gas temperature and the temperature of the combustion air, the following Table can be used to determine combustion efficiency when operating on natural gas.Flue Gas Analysis is performed by inserting a probe into the flue of the furnace, .

Users may conduct a flue gas analysis to detect the concentration of different gases and regulate the burner on a boiler to ensure optimal performance. Flue gas analysis is essential for evaluating air-to-fuel ratios in .Flue Gas Components: Display the calculated percentages of CO2, CO, SO2, NOx, and O2 in the flue gas composition. Environmental Insights: Optionally, provide information about the .A flue gas analyser (FGA) is a vital tool for any Gas Safe Register, OFTEC or HETAS qualified engineer when installing, commissioning, fault finding, repairing or servicing heating appliances. Flue gas analyzers are crucial for sustaining efficient combustion processes, managing emissions, and guaranteeing worker and environmental safety. By comprehending flue gas components and the role of these .

Combustion analysis begins with the measurement of flue gas concentrations and gas temperature, and may include the measurement of draft pressure and soot level. To measure .Determining flue gas concentrations allows legally required emission limit values to be monitored, thus enabling protection of the environment. On the other hand, gas concentrations or gas .Flue gas is the gas that exits via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler, or steam generator to the atmosphere. Quite often, flue .

The following parameters need to be measured, as applicable for the computation of boiler effi-ciency and performance. a) Flue gas analysis 1. Percentage of CO 2 or O 2 in flue gas 2. .Methods of flue gas analysis provide composition data Gas chromatography separates and quantifies gas components; Infrared spectroscopy measures absorption of specific gases; Electrochemical sensors detect O2, CO, and NOx concentrations; Key parameters to evaluate assess combustion process Combustion efficiency measures heat released vs. fuel .1.4.4 Gas volume, diluting effect, reference value 16 1.5 Flue gas (exhaust gas) and its composition 19 1.6 Gross calorific value, net calorific value, efficiency 23 1.7 Dew point, condensate 26 2. Gas analysis for industrial flue gases 29 2.1 Combustion optimization 31 2.2 Process control 34 2.2.1 Process heaters 34 Derek shows us how to use a flue gas analyser correctly and understand the results you get

Carbon capture, utilization, and storage (CCUS) is expected to mitigate CO 2 emissions significantly since CO 2 is captured from the flue gas emitted by power and industrial processes and then either used in manufacturing processes or sequestrated into geographical formations. CO 2 capture is an energy-intensive process, and its energy consumption is .operating parameters of the combustion process that will be modified during the tune-up process. The primary measurements required under the Boiler Area Source Rule are . Additional flue gas component analysis is required when the environmental permit specifies limits on emission components. A common regulated emission component is nitrogen .

emissions and improve the safety of fuel burning equipment. Combustion analysis begins with the measurement of flue gas concentrations and gas temperature, and may include the measurement of draft pressure and soot level. To measure gas concentration, a probe is inserted into the exhaust flue and a gas sample drawn out. Ex- Limestone-gypsum wet flue gas desulfurization (WFGD) process is commonly used in the flue gas desulfurization (FGD) systems of coal-fired power plants [1], which periodically discharges a certain amount of wastewater [2].FGD wastewater is high contaminative and must be treated separately before discharging [3], [4], [5], [6].With the national increment of Hg as .Loss FLUE LOSSES GASES . Created Date: 4/30/2006 9:45:06 AMThe following parameters need to be measured, as applicable for the computation of boiler effi-ciency and performance. a) Flue gas analysis 1. Percentage of CO 2 or O 2 in flue gas 2. Percentage of CO in flue gas 3. Temperature of flue gas b) Flow meter measurements for 1. Fuel 2. Steam 3. Feed water 4. Condensate water 5. Combustion air

Download scientific diagram | Flue gas composition and parameters [1] from publication: Optimized CO2 flue gas separation model for a coal fired power plant | Gas Separation, Fires and Coal .The flue gas enters the lower part of the desulfurization absorption column under the action of the booster fan after being dusted by the dust collector. In the rising process, it comes into full contact with the falling limestone slurry sprayed by the spray. SO 2 in the flue gas is absorbed by the slurry and falls into the slurry pool at the bottom of the column. The production of carbon monoxide (CO) in the flue gases should be kept below 100-ppm air-free, even though the allowable limit in the stack is 400-ppm air-free. search. Search search close search cart. facebook twitter . If the primary air shutters or gas pressure are adjusted, it is imperative that a combustion analysis be performed .

i soft stone mobile app tester

Flue gases released from the boiler chimney contain gases and particulate matter that pollute the environment. Continuous monitoring of stack emission is essential to ensure efficient boiler operations and adherence to environmental norms. . Many key design and operating parameters such as specific collection area, gas velocity (ft/sec) and .

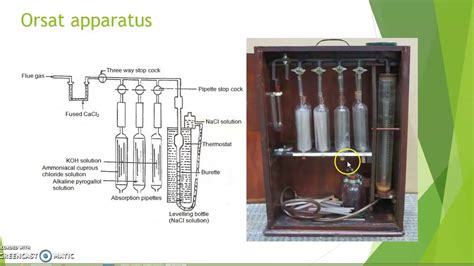

orsat analysis of flue gas

Selected FLUIDBED unit requires a multiple parameters adjustment. . Moreover, the analysis of the flue gas composition at different blend fuel ratios demonstrated that at 1/3 and 1/1 biomass/coal ratios: (1) CO concentration is 26% and 60%, and (2) NO is 50% and 160% higher than in case when biomass presence not exceed 20% of total feed. .

taking your flue gas readings. 3. Carefully observe your condensate trap and empty it of water before it is put away in its bag for the next job. 4. Always connect the flue probe before turning the FGA on to purge the probe and instrument of any residue flue gas. 5. Leave the flue probe connected until theThe measurement of flue gas or combustion process parameters (such as CO in ppm) is a complex challenge – for the measurement technology as well as for the user This is because, in addition to the “classical” tasks such as .The compact flue gas analyzer means your are ideally equipped for industrial flue gas analysis. Products. . Calculation formulae. fuels and parameters Testo flue gas analyzer (pdf, 840.91 kB) Instruction manual easyEmission (pdf, 2.36 MB) testo 340 Firmware update (V1.21, 3.61 MB)

if you come softly test

A one-dimensional mathematical model is adopted to analyse influences of operational parameters on process performance during flue gas recirculation sintering (FGRS).Download scientific diagram | Flue gas composition and parameters [2, 3] from publication: Optimization of post combustion carbon capture process- solvent selection | The reduction of the main .A flue gas analyzer is also used to measure the combustion levels in an internal combustion engine, such as those used in cars, trucks, tractors, generators (gensets) and other motorised equipment. . and unburnt hydrocarbons (CxHy, etc.), as well as the exhaust gas temperature and other important parameters such as the draft and pressure of .Flue gas analysis and heating system applications. There is no alternative to efficient exhaust gas measurement – with up to 4 wireless Smart Probes at the same time. . The measurement of flue gas or combustion process parameters (such as CO in ppm) is a complex challenge – for the measurement technology as well as for the user. This is .

Flue gas analysis plays a pivotal role in optimizing combustion processes, reducing emissions, and adhering to environmental regulations. . SO2 (sulphur dioxide), and particulate matter (dust). Additionally, reference parameters like temperature and O2 (oxygen) levels, and in some cases H2O (water vapor), must also be consistently monitored. flue gas parameters in real operating conditions and the s ubsequent selection of a . . The apparatus for continuous network sampling and analysis of some gas components of waste gases, The .Flue Gas Analysis in Industry. 3 1. Foreword 5 2. The combustion process 6 2.1 Energy and combustion 6 2.2 Combustion plants 8 2.3 Fuels 9 2.4 Combustion air; excess air value 10Flue gas analyzer or exhaust gas analyzer: Trust over 60 years’ experience from Testo, and choose the right model for you here. . Flue gas analysis the easy way. . The measurement of flue gas or combustion process parameters (such as CO in ppm) is a complex challenge – for the measurement technology as well as for the user. This is .

Spraying flue gas desulfurization (FGD) wastewater into the flue duct is a promising technology to achieve zero emission of wastewater by evaporation in thermal power plants.The flue gas analysis is used for thermal process monitoring in process combustion systems, such as in continuous furnaces for the glass, ceramics and construction material sector, or in steel melting and hardening furnaces, etc. . Calculation formulae. fuels and parameters Testo flue gas analyzer (pdf, 840.91 kB) Quickstart Guide testo 350 .

flue gas temperature chart

Resultado da Cinema Cinesercla Shopping Avenida: mapa. Cinesercla Shopping Avenida. Avenida Nóide Ferreira de Cerqueira 5710 44085-052 Feira de .

flue gas analysis parameters|orsat analysis of flue gas